COVID protective screen for hospitals

An open, fast-to-produce protective solution created during the COVID pandemic to support healthcare professionals when certified protective equipment was critically scarce.

During the COVID pandemic, at a time when protective equipment for healthcare workers was in extremely short supply, I decided to contribute by designing a protective face screen. This device was specifically intended to protect against splashes and direct exposure, complementing existing protective measures. It was not designed as a mask, but as an additional physical barrier.

The core objective was speed, accessibility, and openness. The design could be manufactured using common pattern cutting machines and simple transparent plastic materials. To maximize impact, I published the designs openly so that anyone—individuals, makerspaces, or institutions—could produce and distribute them without restrictions.

To ensure compatibility with different cutting machines and production environments, I developed two distinct versions of the design. Each one responds to a specific manufacturing constraint while keeping assembly as simple and intuitive as possible.

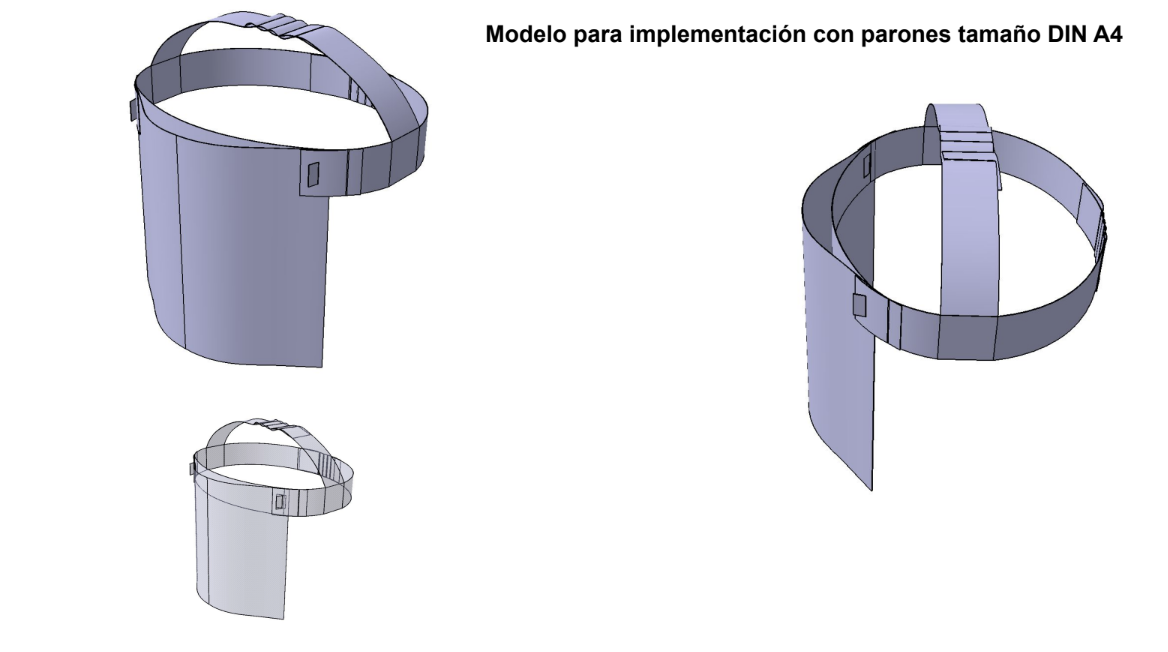

Design for A4 pattern

This version is intended for pattern cutting machines capable of handling up to A2-sized materials. It allows the protective screen to be cut as a single piece, significantly simplifying the assembly process and reducing production time.

One-piece pattern design

This version is designed for cutting machines limited to A4 maximum size. Although it requires assembling several pieces, the process was intentionally kept simple, intuitive, and suitable for rapid manual production.