Standard medical container

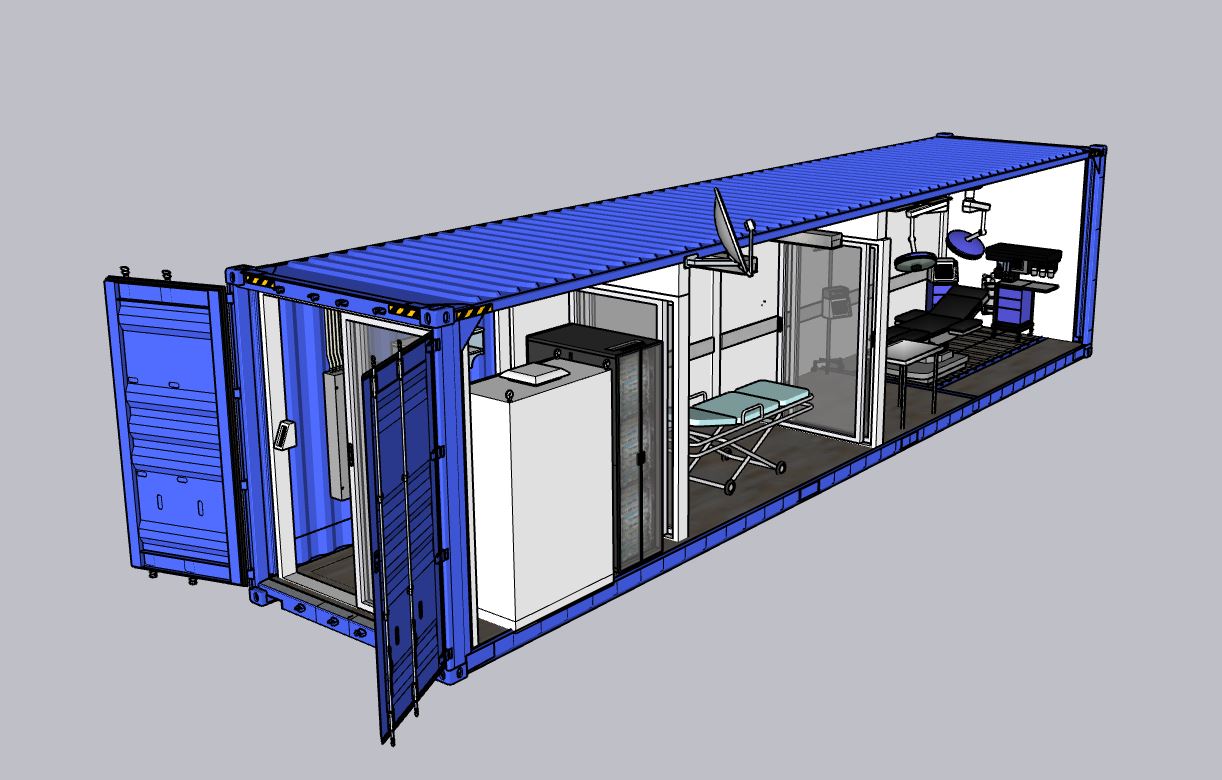

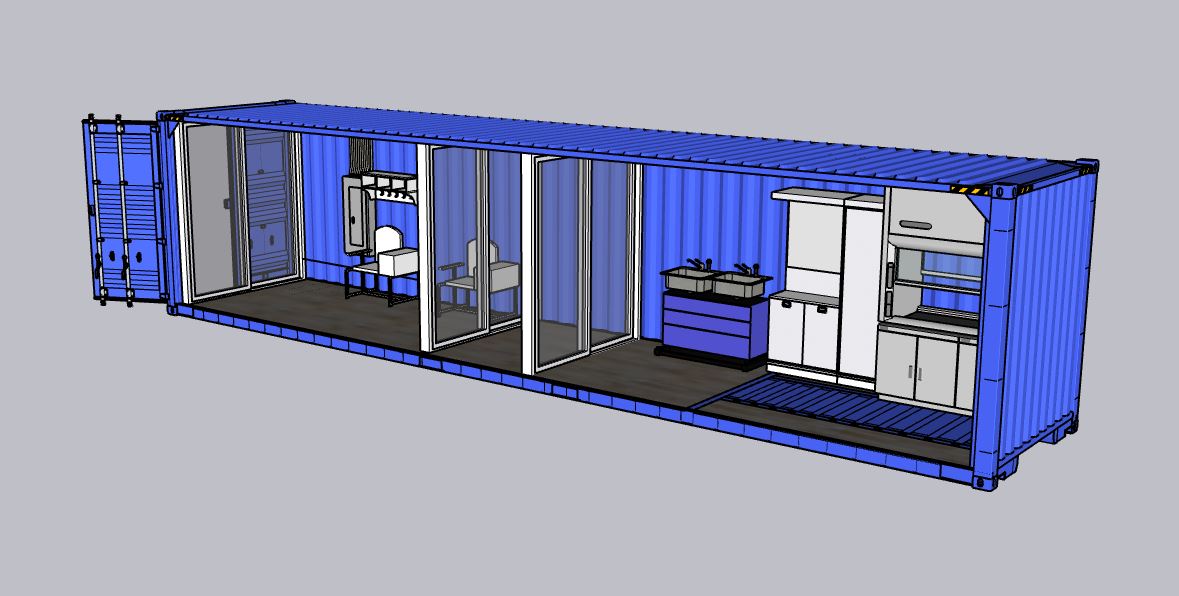

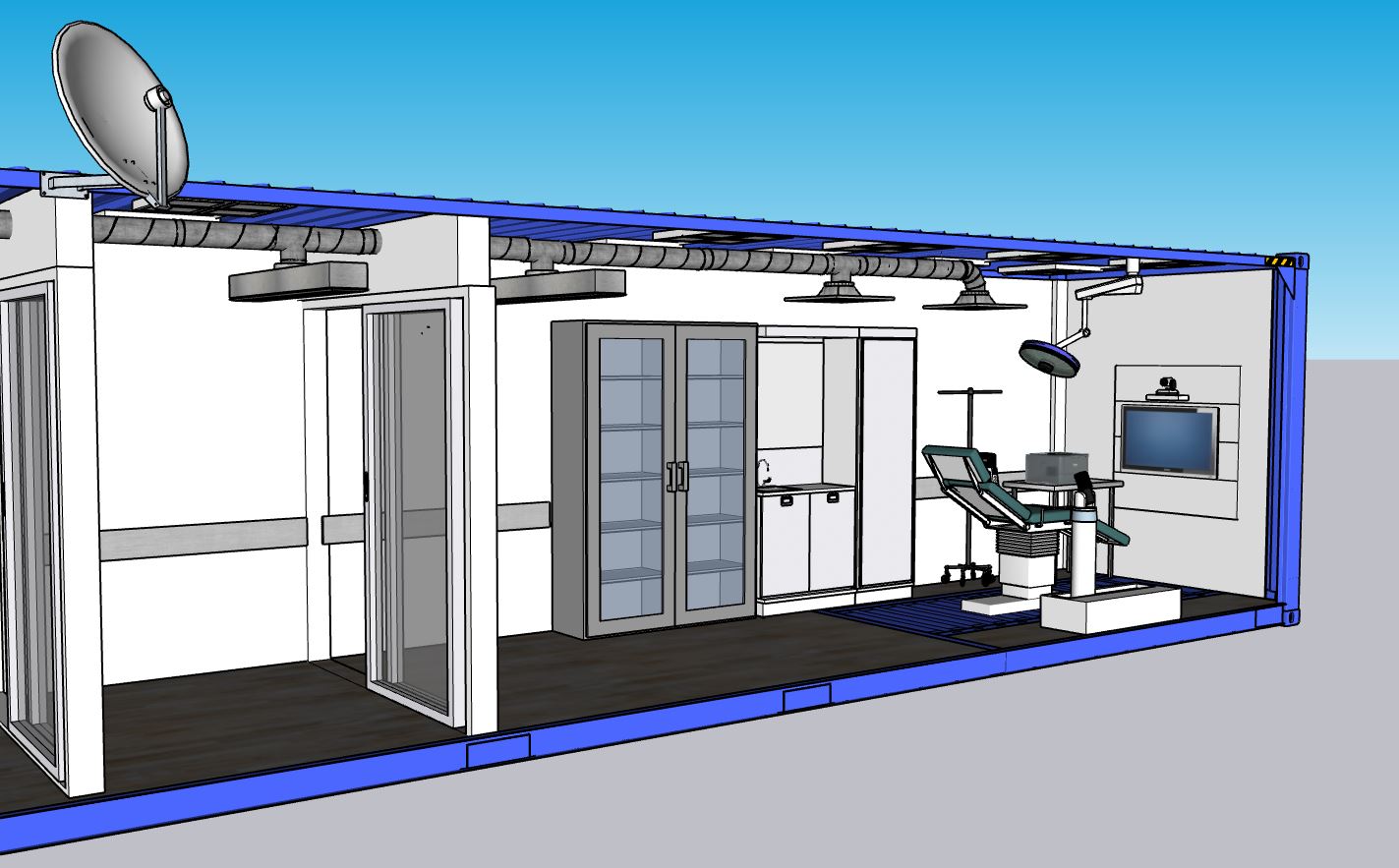

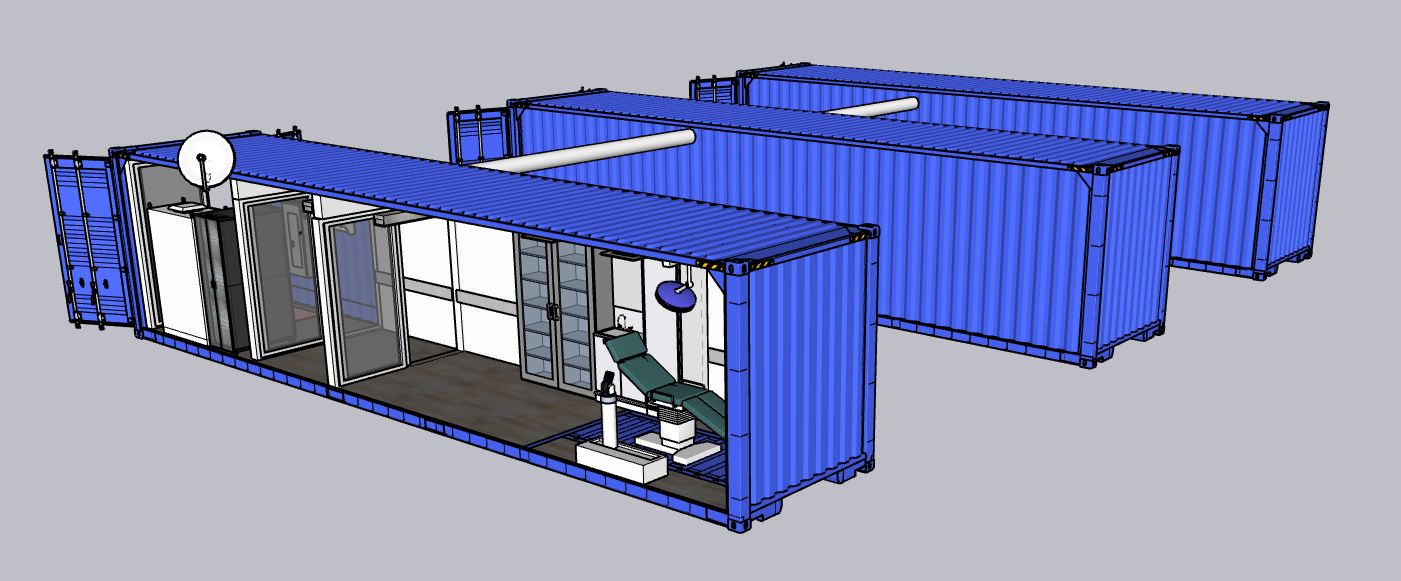

Modular consultation spaces inside standard transport containers — a 3D implementation project focused on realism, logistics feasibility, and practical interior modularity.

I was approached to collaborate on a project that immediately caught my attention. As a product creator, I enjoy the moments where an idea needs to become something tangible — and this one had a clear purpose: to make medical consultation spaces transportable, modular, and deployable anywhere.

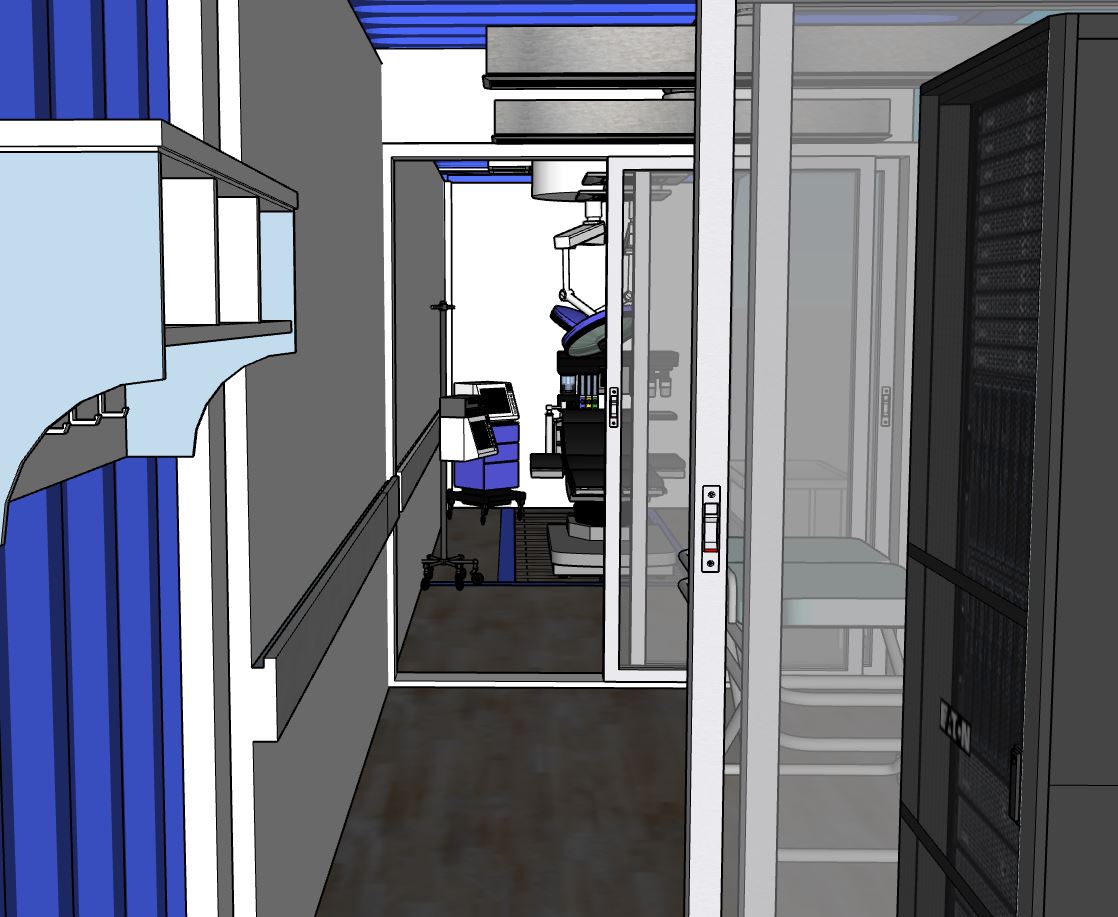

Although I joined as the 3D implementation specialist, it was a privilege to work alongside Aquilino, the patent holder and originator of the concept. My role was to transform the proposal into a realistic 3D model that could be used to communicate the product, test layouts, and visualize how a standard container could become a modular consultation space.

The design challenge was clear: the structure had to remain within the dimensions of a standard transport container, while transforming into a functional interior space that could include a waiting area, a consultation room, and even a restroom. Functionality had to coexist with a clean and professional aesthetic.

Through collaboration and iterative refinements, we reached a model that exceeded what we initially expected. The final 3D output was realistic enough to support detailed walkthroughs and to communicate the concept clearly to potential customers and investors — reducing ambiguity and improving confidence in feasibility.

One of the strongest advantages of the concept was its natural compatibility with global logistics. By using standard containers, the units could be transported almost anywhere, especially valuable in remote or underdeveloped regions where traditional consultation spaces are limited or unavailable.

Working inside the constraints of a container also introduced very specific challenges. Space is limited, so every module had to be carefully designed to maximize usability, flow, privacy, and efficiency. This required constant trade-offs, creative problem-solving, and tight coordination across the team.

The modular approach also allowed configuration based on context: additional seating for in-person consultations, communication tools for remote diagnosis, or autonomous analysis modules to support efficient triage where specialized staff might not be available.

Overall, it was a demanding project — but also a rare opportunity to apply 3D design as a bridge between invention and execution. I’m proud to have contributed to a concept with potential real-world impact in healthcare accessibility.